20 years of experience in developing moulds

SabriScan exists since 1998. Company has acquired extensive experience in designing and manufacturing moulds.

SabriScan offers also optical inserts and after sales services.

SabriScan offers also optical inserts and after sales services.

|

|

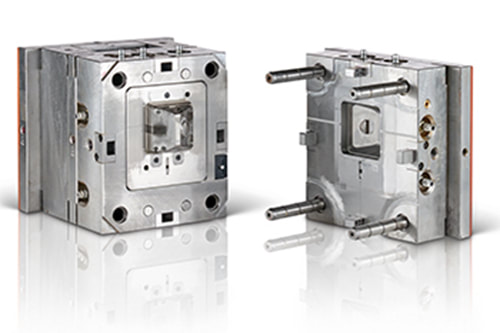

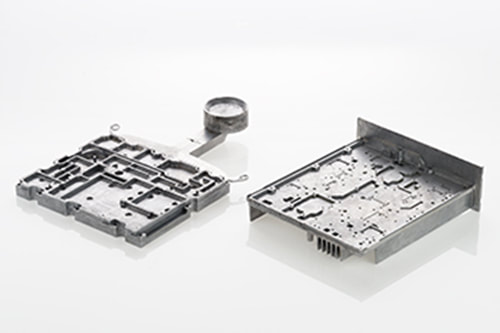

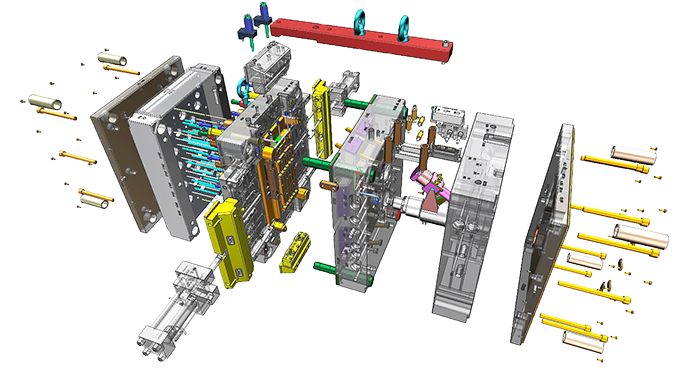

SabriScan makes prototypes and mass production moulds

Moulds

Plastic injection, die casting and special moulds

|

SabriScan is specialised in designing and manufacturing complex moulds with demanding material. SabriScan concept and product design expertise allows it to have clear understanding of customers' specific requirements and provide them with the best mould for their needs.

Characteristic features of SabriScan's mould manufacturing are flexible service, competitive prices and high quality. SabriScan delivers mould projects on time and keeps its promises. Read here about case example of 2-component mould that won the world's best mould award in Germany. |

SabriScan proposes client collaboration and early involvement in clients R&D, product and price design:

• Regular meetings with clients' R&D teams and independent engineering companies • Long-term partnership and continuous dialogue about products and future needs • DFM, mould flow analysis and change recommendations to product design • Feasibility analysis and the design of optimal mould configuration • Training clients on new production methods and material combinations |

MouldCare Services

Maintenance, modification, optimization service, uninterrupted production

|

SabriScan invests heavily in the development of mould maintenance, modification and optimization services both in Finland and in the most significant market areas. The company has launched “MouldCare” services to solve the problematic situation of European customers.

With these services, SabriScan is also able to serve its former competitors who import moulds from China. The problematic lack of local warranty service has thus also been resolved. Thus, all potential players in the mould industry can enjoy MouldCare services, be it a component manufacturer, an injection moulder, an OEM end customer, a Tier1 system supplier or an Asian mould manufacturer. |

MouldCare meets several needs simultaneously. Above all, it achieves a fast start-up of customers' production. Trouble-free and uninterrupted production are other benefits. Product changes and problems during production can be solved with professionalism. Moulds do not physically disturb the customer e.g. as operations expand or make layout changes.

Moulds, meanwhile, can “rest” on SabriScan’s premises and best of all: end-product owners also benefit from MouldCare services when purchasing new moulds. It makes sense to incorporate MouldCare services into mould lifecycle thinking already when planning mould purchases. Here, too, SabriScan professionals will help you! |

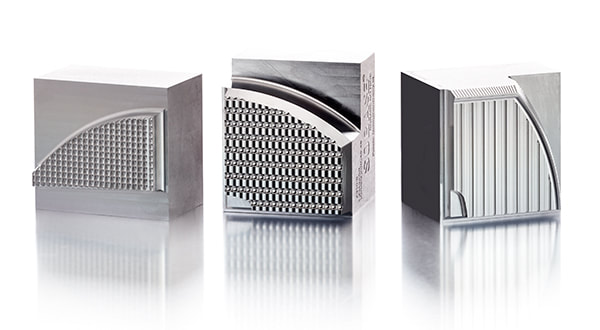

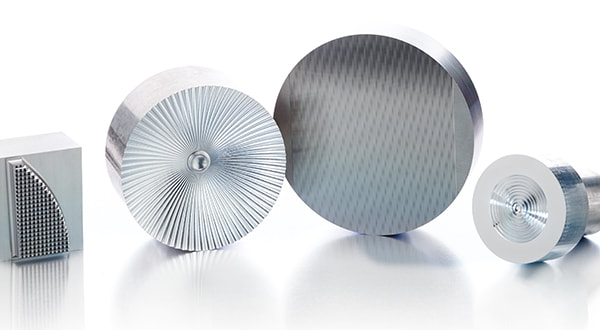

Optical Inserts

Fresnel, micro-optics, prisms, lenses, light guides, sidewalls, bezel and free forms

|

Appreciated by European automotive lighting OEMs

Over the past 15 years, SabriScan has been a trusted partner for leading lighting companies in critical reflective optical inserts. SabriScan inserts are typically used in automotive lighting parts and the company is highly appreciated by European automotive lighting OEMs. SabriScan is constantly developing new optical products and production methods to meet evolving client needs. Today the optical inserts core competence culminates in in-house developed SabriScanMethod® manufacturing. |

SabriScan is constantly developing new optical products and production methods to meet evolving client needs.

|

|

Key product qualities comprise

All products developed by SabriScan Riihimäki

|

Life cycle services

Maintenance, repairs, spare parts and modifications

|

Cost savings and services flexibility

SabriScan serves clients in broad range of mould after sales services covering maintenance, repairs, spare parts and modifications. SabriScan works closely together with clients to find them optimal service setup close to their production sites. This has helped clients in achieving significant results in terms of reduced down time, cost savings and service flexibility. |

SabriScan offers local services in Finland, Romania India, and through partners in Czech, France, U.K. Morocco and Portugal

|

The whole mould life cycle managed by one partner- SabriScan

From feasibility to mass procuction and after sales services

SabriScan moulds, optical inserts and life cycle services form a complete service package taking

full responsibility and covering all client needs regarding the moulds

full responsibility and covering all client needs regarding the moulds

SabriScan services allow clients to focus 100 % on their own core business

|

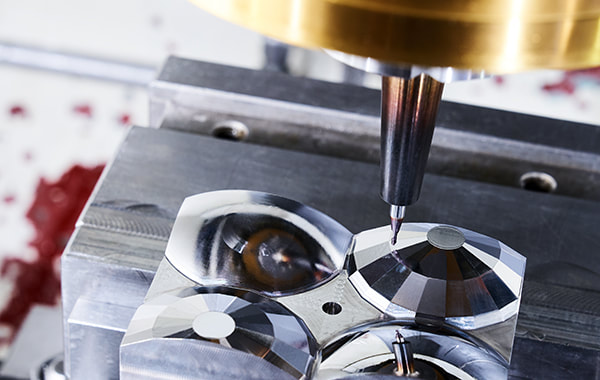

High performance and precision machining

CNC machining, single pieces, repairs, prototypes, small series and reverse engineering

Machining has been over the past two decades SabriScan's core competence. SabriScan realises complex projects with demanding materials including dry cutting, hardened steel parts, gun drilling and deep hole drilling.

Machining relies on 3 and 5 axis CNC milling center, maximum machining area is 1200 x 2000 x 840 mm and lifting capacity reaches up to 10 000 kg.

Machining relies on 3 and 5 axis CNC milling center, maximum machining area is 1200 x 2000 x 840 mm and lifting capacity reaches up to 10 000 kg.

Engineering services

In the core of SabriScan know-how

|

To further leverage the SabriScan machining and operational competence, SabriScan is offering engineering consulting as an add-on service to its existing clients.

SabriScan has been a trusted partner in numerous engagements, clients receiving quick cash-flow gains and significant and long-lasting efficiency gains in their production activities. The services include SabriScan ideal process and Lean-Opex practices consulting including but not limited to:

|