Business concept in Brief

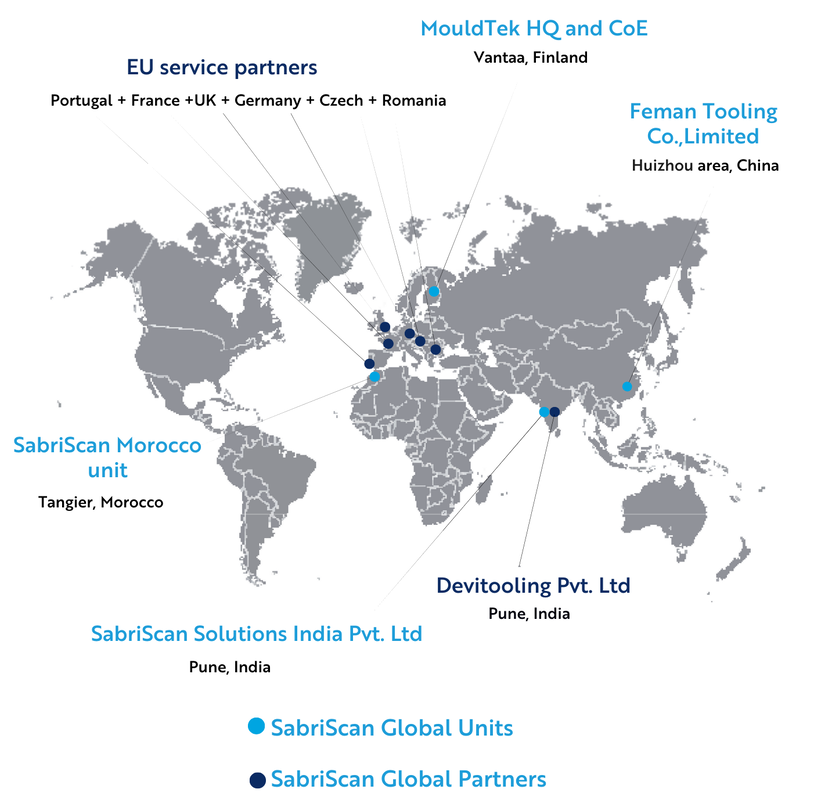

The business model is based on the global delivery of moulds, local service partnerships and a globally sizeable manufacturing capacity.

SabriScan international footprint is created in partnership with its high growth strategic customers. SabriScan wants to expand further and is keen on engaging in partnership with clients who aim international profitable growth.

Global and local services

SabriScan is offering wide range of geographical alternatives to global clients

|

SabriScan HQ and CoE in Finland

• Sales • Engineering support • Project management • Production + testing + pre-series • Maintenance, modifications, repair and spare parts • Engineering (Lean-Opex) services SabriScan Romania, Morocco, India & China units • Sales • Engineering support • Project management • Maintenance, repair and spare parts LCC production partners in China and India • 10 A-level cost efficient partners, with 3000 employees, in the neighbourhood of Shenzen, China and in Pune, India • Production + testing + pre-series • CNC milling, EDM, wire cut, grinding, measuring and injection machines • 15 years experience in building and training the network • Ongoing continuous evaluation of existing partners and identification of new candidates |

Clients are further supported by maintenance, repair and spare parts service partners in UK, Czech and Portugal.

Client service is reinforced by sales agency network covering Sweden, France, Germany, Portugal, India and South Korea. Contact information>> |

Engineering excellency

20 years of experience in developing engineering excellency

SabriScan participates in client product development and supply chain optimisation

Critical part of SabriScan business concept and network machining efficiency development

SabriScan participates in client product development and supply chain optimisation

Critical part of SabriScan business concept and network machining efficiency development

|

Engineering excellency focuses on 4 key areas:

1. Client plastic product design: Focus on design for manufacturing and feasibility studies as part of the mould offering

2. Client supply chain design and Lean-Opex development: Focus on optimising the global supply chain of plastic parts production

3. Internal and Supply-Chain Lean-Opex development: Focus on improving machining efficiency

4. Research and development of critical optical products: and their manufacturability. Focus on automotive sector

|

The value to customer

The business concept delivers undisputed customer value

|

COST EFFICIENCY

SERVICE

RELIABILITY

|

DELIVERY ACCURACY

QUALITY

|